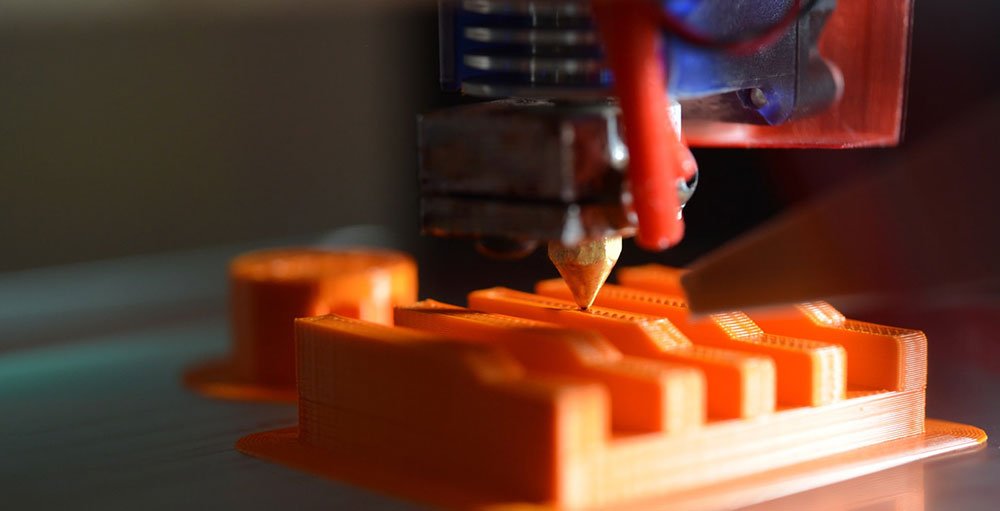

Some managed IT network operators realize that they need 3D printing services. Although the technology isn’t new, many firms have yet to adopt it, and as a result, they are sacrificing their competitive advantage without even realizing it. It’s high time to modernize your company’s tech!

Although 3D printing is still in its infancy, it can assist companies. From personalized items to advertising and design, 3D printing provides a variety of advantages in terms of productivity and developing connections; acquiring a 3D printer is a practical option. In addition, you can learn how to design for 3D printing, among other things.

Whenever you engage with 3-d printing, your client base will be more delighted with the high quality of your product and the hyper-customization options offered. The following are some ways that additive manufacturing can help your company.

Products of excellent quality

Quality is everything to today’s customers. They would prefer to spend more on a fantastic thing than save money on a bad quality thing. 3D printing innovations empower you to give superior grades of minimal expense items to your clients.

The computer-controlled 3D printer makes an indistinguishable generation of the first thing or idea, ensuring the best-in-class quality. This assists with explaining why 3D printers are utilized to fabricate actual items like dental braces, jet engine fuel nozzles, and aircraft and satellite parts.

Creation of prototypes

To lure financial backers and planned shoppers, organizations as often as possible need to deliver models. You might have to fabricate a model for each progression of creation sometimes. On the off chance that your assembling unit is not an in-house business, this may be costly and tedious.

You can foster working models at each stage utilizing 3d printing, and assuming that there is a minor rectification or issue, it doesn’t need a great deal of time or cash to fix it.

Saves money on overhead

Overhead expenditures, including rent, administrative costs, electricity, and other expenses, are a significant concern for businesses. A large plant will require more premises (more rent), more personnel (extraordinary employment expenses), and more upkeep and repairs.

The expenses of additive manufacturing processes like FDM are significantly lower because the printer occupies less space, needs less human inclusion, and has fewer moving parts, making it more straightforward to keep up with and administer.

Given the lower managerial expenses related to 3D printing, your business will be ready to use less expensive rates for your clients.

No more outsourcing

Outsourcing is a must-have for most companies. You may have to order a particular piece or component of your product from a third-party vendor. In the corporate world of the twentieth and twenty-first centuries, outsourcing has become a prevalent trend.

3D printing, on the other hand, has the potential to transform everything. If your organization has its 3D printing section, you can produce the products or elements you require for your manufacturing line at a low cost.

This method also reduces the time it requires you to develop your product because you aren’t dependent on the schedule of another organization.

Enhance productivity

You’ll waste a lot of time, energy, and money repairing mistakes unless your processes are fast and dependable. A defective manufacturing line, for example, may cause delays by stopping production. It could take days, if not weeks, to receive a new replacement.

3D printing is getting more economical and dependable as the cost of printers falls and technology improves. Not only is the printer less prone to break down, but a damaged component may also be easily replaced. This frees you up to concentrate on other crucial aspects of the business.

Less equipment

As it requires fewer elements to produce a similar or higher-quality result, three-dimensional printing technology is more effective than conventional manufacturing gear. It can even be swiftly supplemented or changed to achieve a different result.

Your organization will utilize less space due to having less equipment, which will save your operational costs. Because of additive manufacturing’s outstanding versatility, you won’t need to close down the whole production plant to change one piece of equipment. You can complete it quickly using a multipurpose 3D printer, resulting in cost savings during the manufacturing process.

Increasing Customer Satisfaction

Evaluate what 3d printers can do for your firm’s productivity if all of these arguments aren’t enough to convince you to start looking into 3D printing as a feasible manufacturing technology for your organization. You may notice an improvement in customer experience with the delivery time and the product itself as resource expenses and production time decrease.

Bottom Line

There you have it—seven ways 3D printing can provide your firm with a much-needed competitive edge. It enables you to generate prototypes more quickly, lowers manufacturing costs, takes less labor, and lowers overhead.

Furthermore, effectiveness and productivity have increased dramatically. It benefits to partner with a reputed and professionally maintained IT solutions company to get high-quality and dependable 3D solutions. The organization will supply not only the most up-to-date and most outstanding services but also technical assistance.